Toyota Highlander Service Manual: Adjustment

1. INSPECT SHIFT LEVER POSITION

(a) When shifting the shift lever to each position, make sure that it moves smoothly, can be moderately operated and the position indicator displays correctly.

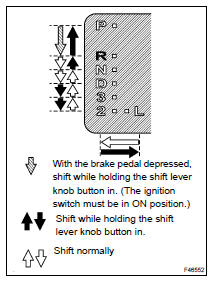

Positions which can be operated without pressing the shift lever knob button

R → N → D, L → 2 → 3 → D → N

Positions which can be operated only while pressing the shift lever knob button

D → 3 → 2 → L, N → R → P

Positions which can be operated only while pressing the shift lever knob button, ignition switch ON and brake pedal depressed

P → R

(b) When starting the engine, make sure that the vehicle moves forward when shifting from N to D position, and moves backward when shifting to R position.

2. ADJUST SHIFT LEVER POSITION

(a) Loosen the nut on the control shaft lever.

(b) Push the control shaft fully downward.

(c) Return the control shaft lever 2 notches to N position.

(d) Set the shift lever to N position.

(e) While holding the shift lever lightly toward the R position side, tighten the shift lever nut.

Torque: 14.7 N*m (150 kgf*cm, 10 ft*lbf)

(f) Start the engine and make sure that the vehicle moves forward when shifting the lever from the N to D position and moves backward when shifting it to the R position.

Overhaul

Overhaul

HINT:

COMPONENTS:

SHIFT LEVER ASSY (See page 40-61 )

1. REMOVE INSTRUMENT CLUSTER FINISH PANEL ASSY CENTER (SEE PAGE71-10 )

2. REMOVE FLOOR CARPET COVER CENTER RH (SEE PAGE71-10 )

3. REMOVE FLOOR ...

Key inter lock solenoid (ATM)

Key inter lock solenoid (ATM)

INSPECTION

1. INSPECT KEY INTER LOCK SOLENOID

(a) Disconnect the solenoid connector.

(b) Connect KLS+ (4) terminal to the batteries' positive (+)

terminal, and KLS- (3) terminal to the battery ...

More about Toyota Highlander:

Using the mechanical key (vehicles with a smart key system)

To take out the mechanical key,

push the release button and take

the key out.

The mechanical key can only be

inserted in one direction, as the

key only has grooves on one side.

If the key cannot be inserted in a

lock cylinder, turn it over and reattempt

to insert it.

After using the m ...