Toyota Highlander Service Manual: Overhaul

HINT: COMPONENTS: See page 27-2 .

1. REMOVE DECK SIDE TRIM COVER LH

2. REMOVE REAR WHEEL

3. SEPARATE REAR STABILIZER LINK ASSY LH

(a) Support the rear axle carrier with a jack.

(b) Remove the nut and disconnect the stabilizer link from the shock absorber.

HINT: If the ball joint turns together with the nut, use a hexagon wrench (5 mm) to hold the stud.

4. REMOVE REAR SHOCK ABSORBER WITH COIL SPRING

(a) FF: Disconnect the skid control sensor connector. Remove the 2 bolts, and disconnect the flexible hose and skid control sensor wire from the shock absorber.

(b) 4WD: Remove the 3 bolts, and disconnect the flexible hose and speed sensor from the shock absorber and rear axle carrier.

(c) Loosen the 2 nuts on the lower side of the shock absorber.

HINT: Do not remove the 2 bolts and 2 nuts.

(d) Remove the 3 nuts.

(e) Lower the rear axle carrier, and remove the 2 nuts and 2 bolts on the lower side of the shock absorber.

(f) Remove the shock absorber with coil spring.

5. FIX REAR SHOCK ABSORBER WITH COIL SPRING

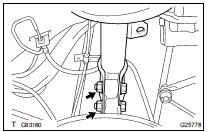

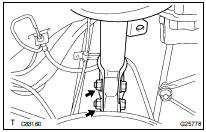

(a) Install the 2 nuts and bolt to the bracket at the lower part of the shock absorber, and secure it in a vise as shown in the illustration to the left.

6. REMOVE SHOCK ABSORBER ASSY REAR LH

(a) Loosen the nut while holding the LH support suspension with a bar taped up so as not to damage the stud bolts.

NOTICE:

- Do not damage the LH support suspension stud bolts.

- Do not remove the nut.

(b) Using SST, compress the coil spring.

SST 09727- 30021 (09727- 00010, 09727- 00021, 09727-00031)

NOTICE: Do not use an impact wrench. It will damage the SST.

(c) Remove the nut, collar and LH support suspension.

(d) Remove the coil spring, spring bumper and insulator lower.

7. INSPECT SHOCK ABSORBER ASSY REAR LH

(a) Compress and extend the shock absorber rod, and check that there is no abnormal resistance or unusual sound.

If there is any abnormality, replace the shock absorber with a new one.

NOTICE: When disposing of the shock absorber, see DISPOSAL on page 27-12 .

8. INSTALL SHOCK ABSORBER ASSY REAR LH

(a) Install the spring bumper.

(b) Install the insulator lower, as shown in the illustration.

(c) Using SST, compress the coil spring.

SST 09727- 30021 (09727- 00010, 09727- 00021, 09727-00031)

NOTICE: Do not use an impact wrench. It will damage the SST.

(d) Install the coil spring to the shock absorber.

HINT: Fit the lower end of the coil spring into the gap of the insulator lower.

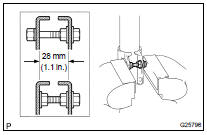

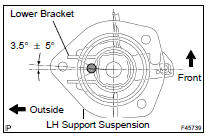

(e) Align the LH support suspension with the shock absorber lower bracket, as shown in the illustration.

HINT: Ensure that the stud bolt is positioned 3.5 to the front of the vehicle as shown in the illustration, and the deviation should be within +/- 5 .

(f) Install the collar to the piston rod.

(g) Temporarily install a new nut.

(h) Remove the SST.

HINT: After removing SST, recheck the direction of the LH support suspension.

(i) Fully tighten the nut while holding the LH support suspension with a bar taped up so as not to damage the stud bolts.

Torque: 49 NVm (500 kgfVcm, 36 ftVlbf)

NOTICE: Do not damage the LH support suspension stud bolts.

9. INSTALL REAR SHOCK ABSORBER WITH COIL SPRING

(a) Install the shock absorber with coil spring and tighten the 3 nuts.

Torque: 58 NVm (590 kgfVcm, 43 ftVlbf)

(b) Install the 2 bolts and nuts to the shock absorber with coil spring.

Torque: 180 NVm (1,840 kgfVcm, 133 ftVlbf)

NOTICE: When installing the nut, keep the bolt from rotating.

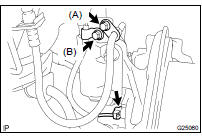

(c) FF: Install the flexible hose and skid control sensor wire with the 2 bolts. Connect the skid control sensor connector.

Torque: Bolt A: 19 NVm (192 kgfVcm, 14 ftVlbf) Bolt B: 5.0 NVm (51 kgfVcm, 44 in.Vlbf)

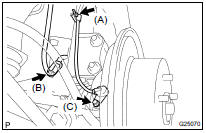

(d) 4WD: Install the flexible hose and speed sensor with the 3 bolts.

Torque: Bolt A: 5.0 NVm (51 kgfVcm, 44 in.Vlbf) Bolt B: 19 NVm (192 kgfVcm, 14 ftVlbf) Bolt C: 8.0 NVm (82 kgfVcm, 71 in.Vlbf)

10. INSTALL REAR STABILIZER LINK ASSY LH

(a) Install the stabilizer link to the shock absorber with the nut.

Torque: 39 NVm (400 kgfVcm, 29 ftVlbf)

HINT: If the ball joint turns together with the nut, use a hexagon wrench (5 mm) to hold the stud.

11. INSTALL REAR WHEEL Torque: 103 NVm (1,050 kgfVcm, 76 ftVlbf)

12. INSPECT REAR WHEEL ALIGNMENT (SEE PAGE 27-5 )

13. CHECK ABS SPEED SENSOR SIGNAL (SEE PAGE 05-765 )

Disposal

Disposal

1. DISPOSE OF SHOCK ABSORBER ASSY REAR LH

(a) Fully extend the shock absorber rod.

(b) Using a drill, make a hole in the cylinder somewhere between

A and B as shown in the illustration to disch ...

More about Toyota Highlander:

Rear axle hub & bearing ASSY LH (FF)

REPLACEMENT

HINT:

COMPONENTS: SEE PAGE 30-4

Replace the RH side by the same procedures with LH side.

1. REMOVE REAR WHEEL

2. SEPARATE RR DISC BRAKE CALIPER ASSY RH

(a) Remove the bolt and separate the flexible hose.

(b) Remove the 2 bolts and brake caliper.

(c) Support the brake cali ...