Toyota Highlander Service Manual: Inspection

1. INSPECT VENTILATION VALVE SUB-ASSY

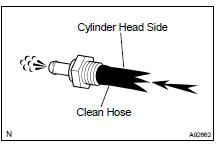

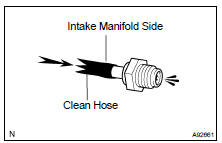

(a) Install a clean hose to the ventilation valve.

(b) Check ventilation valve operation.

- Blow air into the cylinder head side, and check that air passes through easily.

CAUTION: Do not suck air through the valve. Petroleum substances inside the valve are harmful.

- Blow air into the intake manifold side, and check that air passes through with difficulty.

If operation is not as specified, replace the ventilation valve.

(c) Remove the hose from the ventilation valve.

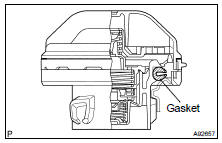

2. INSPECT FUEL TANK CAP ASSY

(a) Visually check if the cap and gasket are deformed or damaged.

If necessary, repair or replace the cap and/or gasket.

3. INSPECT CHARCOAL CANISTER ASSY

(a) Visually check the charcoal canister for cracks or damage.

If cracks or damage is found, replace the charcoal canister assy.

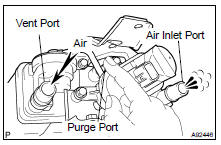

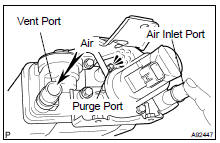

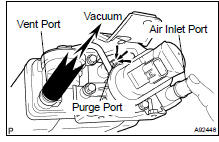

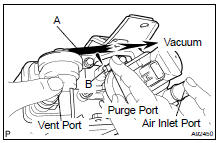

(b) Check charcoal canister operation.

- While holding the purge port closed, blow air (0.39 kPa, 4.0 gf/cm2, 0.06 psi) into the vent port, and check that air flows from the air inlet port.

If the result is not as specified, replace the charcoal canister assy.

- While holding the air inlet port closed, blow air (0.39 kPa, 4.0 gf/cm2, 0.06 psi) into the vent port, and check that air flows from the purge port.

If the result is not as specified, replace the charcoal canister assy.

- While holding the air inlet port closed, apply vacuum (3.43 kPa, 25.7 gf/cm2, 1.01 psi) to the vent port, and check that air is sucked in from the purge port.

If the result is not as specified, replace the charcoal canister assy.

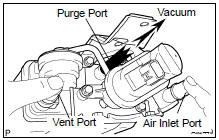

(c) Check the air tightness.

- While holding the vent and air inlet ports closed, apply vacuum (3.43 kPa, 25.7 gf/cm2, 1.01 psi) to the purge port, and check that the vacuum is maintained for 1 minute.

HINT: In order to maintain air tightness, the check should be performed while holding the CCV terminal port closed.

If the result is not as specified, replace the charcoal canister assy.

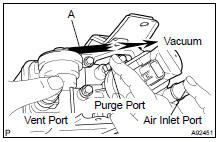

(d) Check the diaphragm.

- Remove the air hose between ports A and B.

- While holding the vent, purge and air inlet ports closed, apply vacuum (1.42 kPa, 11 mmHg, 0.42 in.Hg) into port A, and check that air is sucked in from port B.

- While holding the vent, purge and air inlet ports

closed, apply vacuum (1.42 kPa, 11 mmHg, 0.42

in.Hg) into port A, and measure how long it takes for

vacuum to drop.

Vacuum drop time: 10 seconds or more

If the result is not as specified, replace the charcoal canister assy.

- Reinstall the air hose between ports A and B.

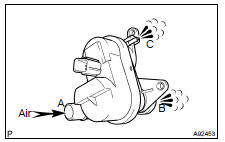

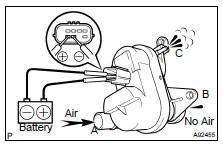

(e) Check pump module operation.

- Check that air flows from port A to ports B and C.

If the result is not as specified, replace the pump module.

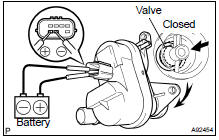

- Apply battery positive voltage across the terminals.

- Check that the valve is closed.

If the result is not as specified, replace the pump module.

- Check that air does not flow from port A to port B.

- Check that air flows from port A to port C.

If the result is not as specified, replace the pump module.

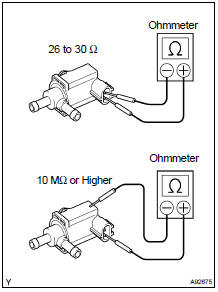

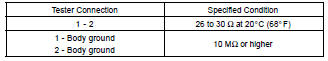

4. INSPECT VACUUM SWITCHING VALVE ASSY FOR EVAP

(a) Measure the VSV resistance between the terminals.

Standard:

If the resistance is not as specified, replace the VSV assy.

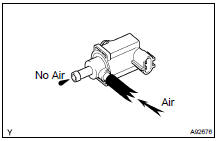

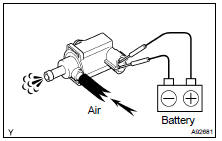

(b) Check VSV operation.

- Check that air does not flow from the port as shown in the illustration.

If the result is not as specified, replace the VSV assy.

- Apply battery positive voltage across the terminals.

- Check that air flows from the ports.

If the result is not as specified, replace the VSV assy.

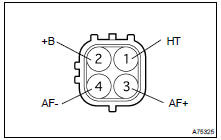

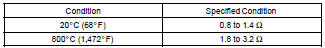

5. INSPECT A/F SENSOR (BANK 1 SENSOR 1)

(a) Measure the resistance between terminals 1 (HT) and 2 (+B).

Standard:

If the result is not as specified, replace the sensor.

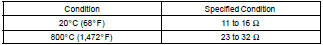

6. INSPECT HEATED OXYGEN SENSOR (BANK 1 SENSOR 2)

(a) Measure the resistance between terminals 1 (HT) and 2 (+B).

Standard:

If the result is not as specified, replace the sensor.

On-vehicle inspection

On-vehicle inspection

1. INSPECT AIR-FUEL RATIO COMPENSATION SYSTEM

(a) Measure the voltage between the terminals of the ECM

connectors.

Standard:

NOTICE:

Connect test leads to the connector's backside. The co ...

Charcoal canister ASSY (2AZ-FE)

Charcoal canister ASSY (2AZ-FE)

REPLACEMENT

1. REMOVE EXHAUST PIPE ASSY CENTER

(a) Remove the 4 bolts and 2 compression springs.

(b) Remove the exhaust pipe center from the 4 exhaust pipe

supports.

(c) Remove the 2 gaskets from ...

More about Toyota Highlander:

Initialization

The following items must be initialized for normal system operation

after such cases as the battery being reconnected, or maintenance

being performed on the vehicle:

Item

When to initialize

Power back door*

After reconnecting or changing

the battery

...