Toyota Highlander Service Manual: Inspection

1. INSPECT INTAKE AIR CONTROL VALVE ASSY NO.2

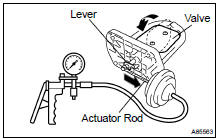

(a) Apply 26.7 kPa (200 mmHg, 7.9 in.Hg) of vacuum to the actuator. Check if the actuator rod pulls the lever and causes the valve to rotate open, as shown in the illustration.

(b) One minute after applying the vacuum, check that the actuator rod does not return.

If the result is not as specified, replace the IAC valve assy No.

2.

2. INSPECT AIR CLEANER CAP SUB-ASSY

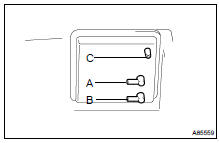

(a) Cover port C with your finger and blow air into port B.

Check that air flows out of port A.

(b) Cover port C with your finger and blow air into port A.

Check that air does not flow out of port B.

(c) Cover ports A and C with your fingers, and apply 60 kPa (450 mmHg, 18 in.Hg) of vacuum to port B. Check that there is no change in the vacuum after one minute.

If the result is not as specified, replace the air cleaner cap.

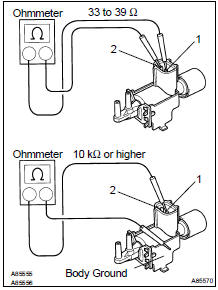

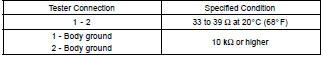

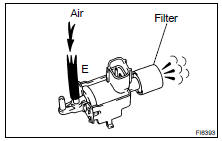

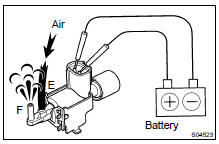

3. INSPECT VACUUM SWITCHING VALVE ASSY FOR IAC VALVE NO. 2

(a) Measure the VSV resistance.

Standard:

If the result is not as specified, replace the VSV assy.

(b) Check VSV operation.

- Check that air flows from port E to the filter.

If the result is not as specified, replace the VSV assy.

- Apply battery voltage across the terminals.

- Check that air flows from port E to port F.

If the result is not as specified, replace the VSV assy.

On-vehicle inspection

On-vehicle inspection

1. INSPECT INTAKE AIR CONTROL SYSTEM

(a) Using a 3-way connector, connect a vacuum gauge to the

actuator hose.

(b) Connect the hand-held tester to the DLC3.

(c) Start the engine.

(d) On the h ...

Intake air control valve ASSY NO.2 (3MZ-FE)

Intake air control valve ASSY NO.2 (3MZ-FE)

REPLACEMENT

1. REMOVE INTAKE AIR CONTROL VALVE ASSY NO.2

(a) Remove the 3 bolts and nut.

(b) Turn the lever to the closed position as shown in the illustration

and pull out the IAC valve.

(c) ...

More about Toyota Highlander:

Disposal

HINT:

Disposal procedure of the RH side is the same as that for the LH

side.

The procedures listed below are for the LH side.

When scrapping a vehicle equipped with the SRS or disposing of the

curtain shield airbag assy LH,

be sure to deploy the airbag first in accordance with the pr ...