Toyota Highlander Service Manual: Brake master W/Plate cylinder sub-ASSY

REPLACEMENT

HINT: COMPONENTS: See page 32-18 .

1. REMOVE FRONT SUSPENSION BRACE SUB-ASSY UPPER CENTER

(a) Remove the 4 nuts and the front suspension brace subassy upper center.

2. REMOVE AIR CLEANER ASSY (2AZ-FE ENGINE TYPE) (SEE PAGE 14-24 )

3. REMOVE AIR CLEANER CAP SUB-ASSY (3MZ-FE ENGINE TYPE) (SEE PAGE 14-149 )

4. REMOVE AIR CLEANER FILTER ELEMENT SUB-ASSY (3MZ-FE ENGINE TYPE) (SEE PAGE 14-149 )

5. REMOVE AIR CLEANER CASE (3MZ-FE ENGINE TYPE) (SEE PAGE 14-149 ) 6. DRAIN BRAKE FLUID

NOTICE: Wash brake fluid off immediately if it adheres to any painted surface.

7. REMOVE BRAKE MASTER W/PLATE CYLINDER SUB-ASSY

(a) Using SST, disconnect the 2 brake tubes from the brake master w/plate cylinder sub-assy.

SST 09023-00101

(b) Disconnect the brake fluid level warning switch connector.

(c) Remove the 2 nuts, then pull at the check valve bracket and the brake master w/plate cylinder assy.

8. INSPECT AND ADJUST BRAKE BOOSTER PUSH ROD

NOTICE: Make an adjustment with the brake booster assy having no vacuum. (Depress the brake pedal several times with the engine stopped.)

HINT: Adjustment of the brake booster push rod is performed when the brake master cylinder sub-assy is replaced with a new one.

The adjustment is not necessary when the brake master cylinder sub-assy is reinstalled and the brake booster assy is replaced with a new one.

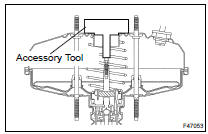

(a) Apply the chalk to the tip of an accessory tool.

HINT: An accessory tool is enclosed with a new brake master cylinder sub-assy .

(b) Place the accessory tool to the brake booster assy.

(c) Measure the clearance between the brake booster push rod and accessory tool.

Clearance: 0 mm (0 in.)

HINT: Adjust the clearance in following cases:

- If there is a clearance between the accessory tool and the shell of the brake booster (floating accessory tool), the push rod is protruding too far.

- If the chalk does not stick on the tip of the brake booster push rod, the push rod protrusion is insufficient.

(d) If clearance is outside the specified range, fix the push rod using SST and adjust the length of the protruding adjusting bolt.

SST 09737-00020

HINT: When adjusting the push rod, depress the brake pedal sufficiently so that the push rod sticks out.

9. INSTALL BRAKE MASTER W/PLATE CYLINDER SUB-ASSY

(a) Install the brake master w/ plate cylinder sub-assy and the check valve bracket with the 2 nuts.

Torque: 13 NVm (130 kgfVcm, 9 ftVlbf)

(b) Using SST, connect the 2 brake tubes to the brake master w/ plate cylinder assy.

SST 09023-00101

Torque: 15 NVm (155 kgfVcm, 11 ftVlbf)

(c) Connect the brake fluid level warning switch connector.

10. FILL RESERVOIR WITH BRAKE FLUID (SEE PAGE 32-4 )

11. BLEED MASTER CYLINDER (SEE PAGE 32-4 ) SST 09023-00101

12. BLEED BRAKE LINE (SEE PAGE 32-4 )

13. BLEED BRAKE ACTUATOR ASSY (SEE PAGE 32-4 )

14. CHECK FLUID LEVEL IN RESERVOIR (SEE PAGE 32-4 )

15. INSTALL AIR CLEANER ASSY (2AZ-FE ENGINE TYPE) (SEE PAGE 14-24 )

16. INSTALL AIR CLEANER CASE (3MZ-FE ENGINE TYPE) (SEE PAGE 14-149 )

17. INSTALL AIR CLEANER FILTER ELEMENT SUB-ASSY (3MZ-FE ENGINE TYPE) (SEE PAGE 14-149 )

18. INSTALL AIR CLEANER CAP SUB-ASSY (3MZ-FE ENGINE TYPE) (SEE PAGE 14-149 )

19. INSTALL FRONT SUSPENSION BRACE SUB-ASSY UPPER CENTER

(a) Install the front suspension brace sub-assy upper center with the 4 nuts.

Torque: 80 NVm (816 kgfVcm, 59 ftVlbf)

20. CHECK BRAKE FLUID LEAKAGE

21. CHECK FLUID LEVEL IN RESERVOIR (SEE PAGE 32-4 )

Brake pedal sub-assy

Brake pedal sub-assy

ADJUSTMENT

1. CHECK AND ADJUST BRAKE PEDAL HEIGHT

(a) Check brake pedal height.

Pedal height from asphalt sheet:

150 to 160 mm (5.906 to 6.299 in.)

(b) Adjust brake pedal height.

Di ...

More about Toyota Highlander:

Phone display settings

Display the "phone/message settings" screen.

Select "phone display settings".

Select the desired item to be set.

Change the incoming call

display.

ŌĆ£Full screenŌĆØ: when a call is

received, the hands-free screen

is displayed and can be operated

on the ...