Toyota Highlander Service Manual: On-vehicle inspection

1. INSPECT REFRIGERANT VOLUME

(a) Check the sight glass on the cooler refrigerant liquid pipe A.

Test conditions:

- Engine is running at 1,500 rpm

- Blower speed control switch is at "HI"

- A/C switch is ON

- Temperature control dial is at "MAX. COOL"

- Doors are fully open

|

Item |

Symptom |

Amount of refrigerant |

Corrective Actions |

|

1 |

Bubbles exist | Insufficient* | (1) Check for gas leakage and repair if necessary (2) Add refrigerant until bubbles disappear |

| 2 | No bubbles exist | Empty, insufficient or excessive | Refer to 3 and 4 |

| 3 | No temperature difference between compressor inlet and outlet | Empty or nearly empty | (1) Check for gas leakage with gas leak detector and repair if necessary (2) Add refrigerant until bubbles disappear |

| 4 | Considerable temperature difference between compressor inlet and outlet | Proper or excessive | Refer to 5 and 6 |

| 5 | Immediately after air conditioning is turned off, refrigerant clears | Excessive | (1) Discharge refrigerant (2) Remove air and supply proper amount of purified refrigerant |

| 6 | Immediately after air conditioning is turned off, refrigerant foams and then becomes clear | Proper |

- |

*: Bubbles in the sight glass with ambient temperatures higher than usual can be considered normal if cooling is sufficient.

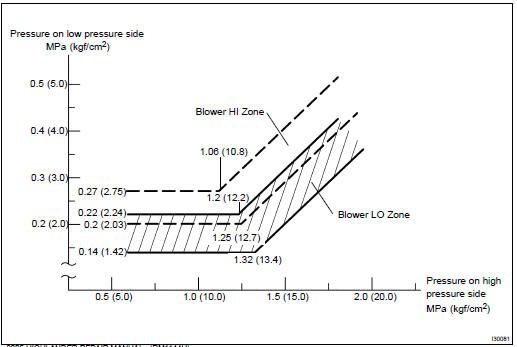

2. INSPECT REFRIGERANT PRESSURE WITH MANIFOLD GAUGE SET

(a) This is a method in which the trouble is located by using a manifold gauge set. Read the manifold gauge pressure when these conditions are established.

Test conditions:

- Temperature at the air inlet with the switch set at RECIRC is 30 to 35C (86 to 95F)

- Engine is running at 1,500 rpm

- Blower speed control switch is at "HI"

- Temperature control dial is at "COOL"

- A/C switch is ON

- Doors are fully open

- Normally functioning refrigeration system

Gauge reading: Low pressure side: 0.15 to 0.25 MPa (1.5 to 2.5 kgf/cm2) High pressure side: 1.37 to 1.57 MPa (14 to 16 kgf/cm2)

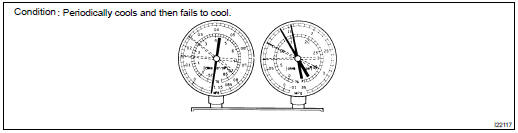

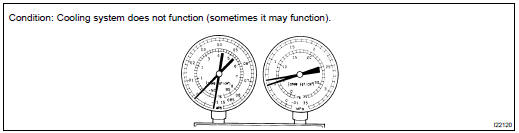

- Moisture is present in refrigeration system

|

Symptom |

Probable cause |

Diagnosis |

Corrective Actions |

| During operation, pressure on low pressure side cycles between normal and vacuum | Moisture in refrigeration system

freezes at expansion valve orifice,

causing a temporary stop of cycle. However, when it melts, normal state is restored. |

|

|

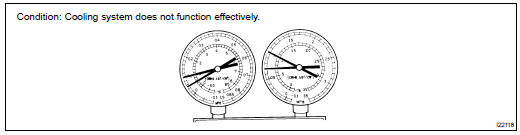

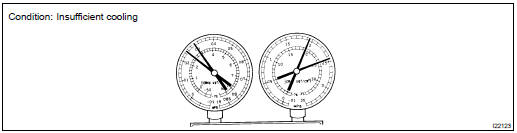

- Insufficient cooling

|

Symptom |

Probable cause |

Diagnosis |

Corrective Actions |

|

Gas leakage in refrigeration system |

|

|

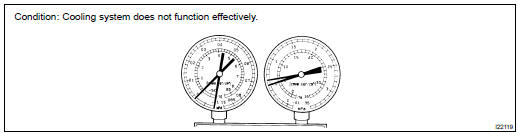

- Poor circulation of refrigerant

|

Symptom |

Probable cause |

Diagnosis |

Corrective Action |

|

Refrigerant flow is obstructed by dirt in the receiver | Receiver is clogged | Replace condenser |

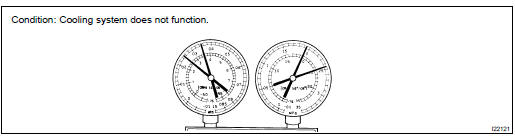

- Refrigerant does not circulate

|

Symptom |

Probable cause |

Diagnosis |

Corrective Actions |

|

|

Refrigerant does not circulate |

|

- Refrigerant is overcharged or cooling effectiveness of condenser is insufficient

|

Symptom |

Probable cause |

Diagnosis |

Corrective Actions |

|

|

|

|

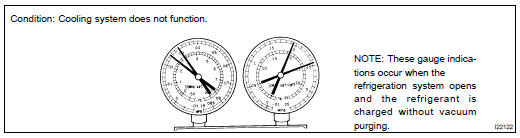

- Air present in refrigeration system

|

Symptom |

Probable cause |

Diagnosis |

Corrective Actions |

|

Air in system |

|

|

- Expansion valve malfunction

|

Symptom |

Probable cause |

Diagnosis |

Corrective Actions |

|

Trouble in expansion valve |

|

Check expansion valve |

- Defective compressor

|

Symptom |

Probable cause |

Diagnosis |

Corrective Actions |

|

Internal leak in compressor |

|

Repair or replace compressor |

Gauge readings (Reference)

Refrigerant

Refrigerant

...

Replacement

Replacement

1. DISCHARGE REFRIGERANT FROM REFRIGERATION SYSTEM

(a) Turn the A/C switch on.

(b) Operate the cooler compressor at an engine rpm of approximately 1,000 for 5

to 6 minutes to circulate

the refrig ...

More about Toyota Highlander:

Inspection

1. INSPECT MASS AIR FLOW METER

(a) Check the output voltage.

Apply battery voltage across terminals 1 (+B) and 2

(E2G).

Connect the positive (+) tester probe to terminal 3

(VG), and negative (-) tester probe to terminal 2

(E2G).

Blow air into the Mass Air Flow (M ...